Smart Drone Energy Survey (SDES) revolutionises energy audit techniques for a diverse range of large-scale structural and thermal inspections on a variety of faults and thermal leakages.

The building sector is responsible for 40% of overall global energy consumption. Building defects including heat loss, moisture, and air leakage, account for inefficient space heating and cooling resulting in excessive energy consumption and adding to associated greenhouse gas emissions.

Building inspections and energy surveys are performed to detect building defects such as cracks, moisture and air losses, however, being highly labour intensive and time consuming, these existing survey methods are not suitable for large-scale audits.

Smart Drone Energy Survey (SDES)

SDES provide a time-efficient, cost-effective, and near-autonomous solution to large scale building façade inspections.

SDES utilises onboard low-power hardware that includes sophisticated sensors and cameras that are capable of:

- Thermographic 3D reconstruction of buildings in real-time

- Autonomous detection of various building faults though embedded Artificial Intelligence (AI)

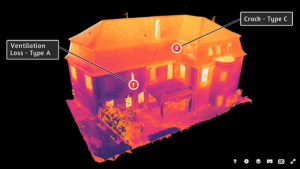

Thanks to the monocular photogrammetry technique superimposed with thermographic imagery, drones can capture and produce a fully stitched and textured 3D model as it surveys a façade. This helps in quantitative building energy audits and more detailed fault diagnosis. An example of a result of this type of survey is shown in Figure 1.

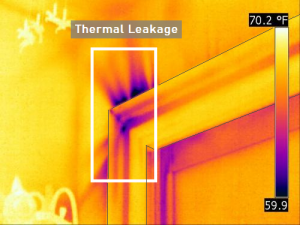

The on-board computer vision hardware enables the drone to instantaneously detect and identify building defects (such as heat losses on windows) using real-time Transfer Learning (TL), a pretrained Machine Learning (ML) method. An example of a result of this technique is shown in Figure 2.

The transfer learning (TL) method can be further adapted for newer/specific/custom faults by simply adding training data with images and their corresponding labels to the TL model.

This technology can be adopted not only in building surveys, but for any other structural inspection that would normally be time-consuming, labour-intensive, or situated in hazardous or unreachable areas.

Figure 1 – Faults annotation displayed on thermal 3D model produced using a drone survey

Figure 2 – Thermal Leakage detected through embedded transfer learning