Transforming ideas from conception to production, Free Running Buildings use Computer Aided Design (CAD) software to develop designs ready for 3D printing software.

3D printing is advantageous when compared with traditional manufacturing benefitting from rapid manufacturing, cost savings, increased testing, and iterative design capabilities. The technology radically reduces the time taken to produce custom parts resulting in designs being iterated upon far quicker.

With two high-end 3D printing technologies on-site, we offer a wide range of 3D product design, rapid prototyping, and printing.

Fusion Deposition Modelling (FDM) / Fused Filament Fabrication (FFF)

The most common method of 3D printing. The physical object is created by the machine depositing thermoplastics directly on to the build plate. This method is cost effective and suitable for prototypes, design verification, iterative design, and low volume batch production.

Machine specifications and features:

|

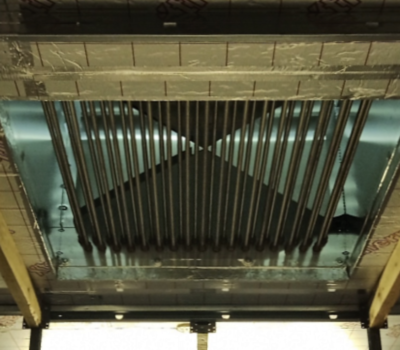

3D printing for building |

Low Force Stereolithography (LFS)

Low Force Stereolithography (LFS) is favoured for its ability to produce smooth surface finishes and complex designs. A laser is used to selectively cure layers of liquid photopolymers on to a build plate to replicate the computational design. The printing process is followed by a chemical bath to remove excess resin followed by post-curing in an ultra-violet oven to generate a stronger, more structurally stable item. The finish quality and resolution of detail is ideal for visual prototyping and product development.

Machine specification and features:

- 145 x 145 x 185 mm build volume

- XY resolution of 25 microns

- Laser spot size 85 microns

- 25 – 300 micron layer thickness

- Post print washing and curing to generate quality finished product